Reducing Postharvest Losses during Storage of Grain Crops to Strengthen Food Security in India

As increasing populations in India , puts pressure on our food supplies. About one-third of the total food produced for human consumption is wasted, with the majority of loss in developing countries occurring between harvest and the consumer. Reducing the postharvest losses, could be a sustainable solution to increase food availability, reduce pressure on natural resources, eliminate hunger and improve farmers’ livelihoods.

Post-harvest losses account for about 10% of total food grains due to unscientific storage, insects, rodents, micro-organisms etc., In India, annual storage losses have been estimated14 -million tones worth of Rs. 7,000 crore in which insects alone account for nearly Rs. 1,300 crores.

Use of scientific storage methods can reduce these losses to as low as 1%–2%.

Improper food storage leads to loss of quality. An example of large stores in India in which porous jute bags of grain are stacked and inadequately protected from rain, leading to high moisture content and even to sprouting (inset)

Grain is usually stored for several months after harvest, which is much longer than other grain post-harvest steps. Also, the grain is minimally monitored during storage. Thus, proper grain storage conditions are needed to minimize grain losses.

Factors that play a crucial role in storage losses are below

· Physical Factors—Temperature, Moisture, and Oxygen

Physical factors such as oxygen, moisture, relative humidity, and temperature have a major impact on the storability of grain. Physical factors influence the conditions for insect multiplication and mold growth during grain storage, which eventually affects the storability of the grain.

· Biological Factors—Insect and Rodent Activity, and Mold Growth during Grain Storage

Insects/pests and rodents are the major factors affecting grain quality and grain losses in developing countries. In most storage practices, insect growth and mold formation take place within the system. However, depending upon the storage types and conditions, their active period differs.

- Mold Formation and Growth

Mold formation in stored grain can produce different mycotoxins, which are toxic chemicals unsuitable for human consumption. In addition, mold generates other problems besides mycotoxins, such as dry matter loss, odor, and a loss of nutritional value. Thus, the presence of active mold in stored grain can greatly limit grain usage due to quality loss and mycotoxin formation.

Currently the grains are stored in three kinds of bags jute sacks , woven plastic sacks of Hdpe (High density polyethylene) and and pp (polypropylene).

The below study was undertaken to assess the suitability of commodity storage, insect penetration and variation in fungal profile in paddy, rice and wheat stored in three packages such as PP, HDPE and Jute sacks at ambient (RT) and accelerated conditions. By Ramaswamy K, Uma G, Singh V, Gunasekaran N .Studies on the Selection of Plastic Woven Sacks for Storage of Food CommoditiesStudies on the Selection of Plastic Woven Sacks for Storage of Food Commodities Biosci Biotechnol Res Asia 2008;6(1). Biosci Biotechnol Res Asia 2008;6(1).

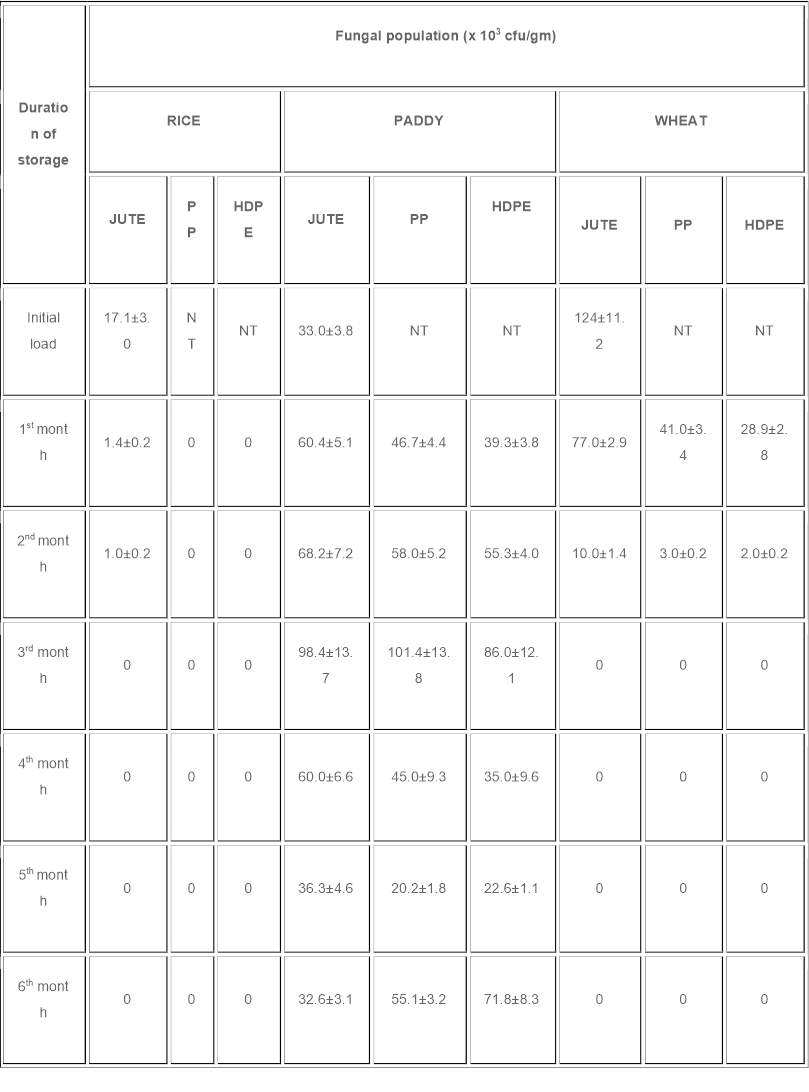

Table 1. Fungal population in rice, paddy and wheat stored for six months at ambient temperature (RT)

Values represent the mean ± standard deviation of triplicate plates

NT= Not Tested

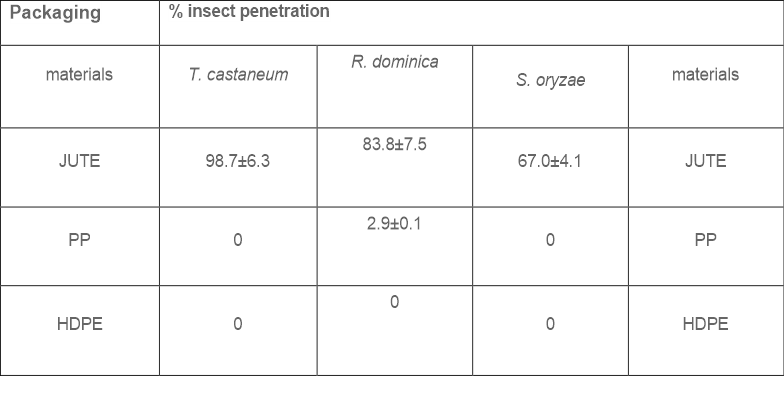

Table 2: Insect penetration through different packaging material.

Represent the mean ± standard deviation of five replicate samples.

Conclusion

In summary, the present findings revealed that there was a significant difference between the higher numbers of fungal colonies associated with Jute sacks, than woven PP and HDPE sacks. Among the three commodities stored at ambient temperature (RT), paddy harbored higher number of fungal colonies than rice and wheat throughout the storage period.

Based on the results of both fungal and insect penetration studies it can be concluded that woven HDPE sacks have many microbiological and physiological advantages over the traditional Jute sacks to merit their use for commodity storage. This would probably save defects and losses due to insects and fungi which were estimated to be over 30% of the annual harvest.

If you have any questions or queries we will always be happy to help. Feel free to contact us by telephone or email and we will be sure to get back to you as soon as possible.